Overview

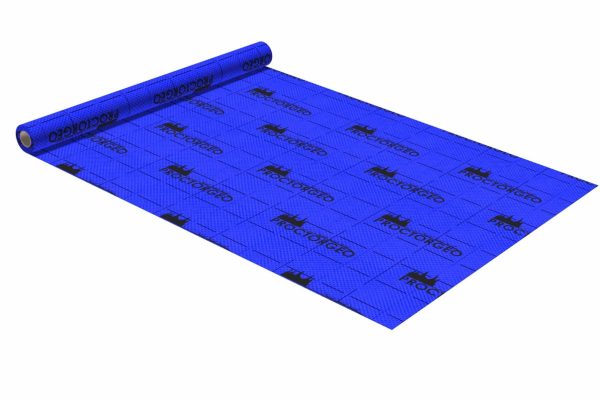

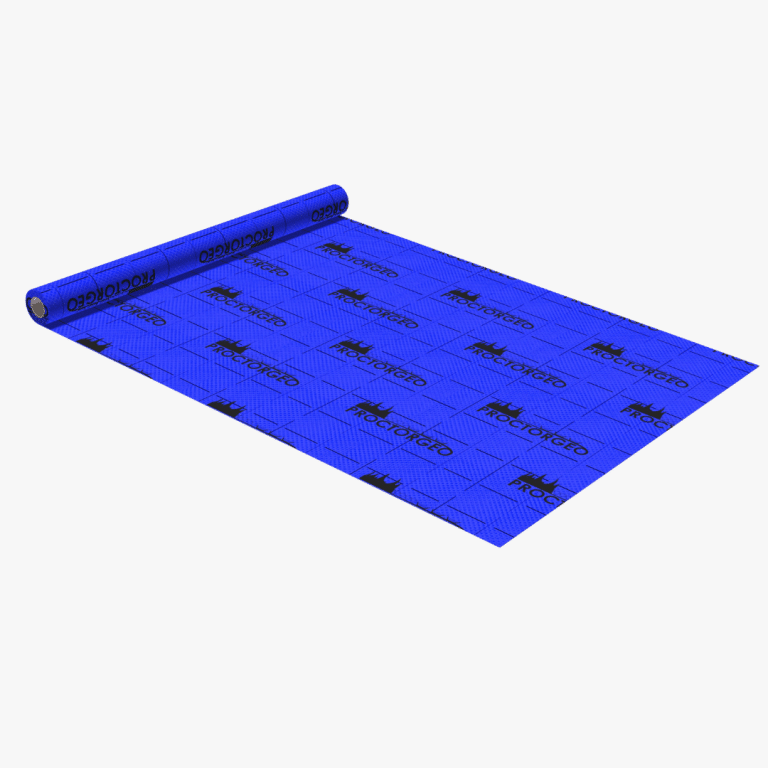

ProctorGeo Vap120 is a light duty vapour retarder and convection barrier. The high air & water vapour resistance of the two-layer polyolefin non-woven membrane resists the flow of vapour by both diffusion and air movement through wall, ceiling and floor assemblies thus helping protect the building fabric and insulation from condensation and related problems such as mould, timber rot, corrosion and loss of thermal resistance.

When installed as a continuous layer, ProctorGeo Vap120 will help form an airtight layer reducing the loss of heated air or cooled air from the building thus improving the energy efficiency of the building enclosure.