Overview

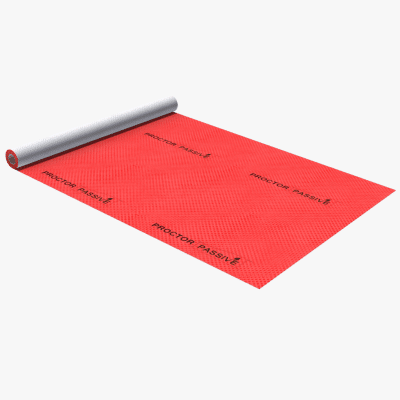

CodeMark Certified, ProctorPassive SmartVap 100 (SmartVap) is a two layer AS4200.1 compliant light duty air barrier and variable vapour diffusion resistance retarder.

Variable vapour diffusion resistance

The functional layer of SmartVap is a polyamide film. Such films passively adjust vapour diffusion resistance depending on the humidity where located. The polyamide absorbs water vapour from the air, opening the molecular pores thus adjusting vapour diffusion resistance according to ambient humidity conditions.